Automated Visual Inspection Systems: Driving Zero-Defect Production

For global manufacturers, poor quality control drains up to 20% of sales and exposes brands to costly recalls and reputational damage. A single recall can cost not just money but reputation. Here’s the question every factory leader is asking: How do we guarantee zero-defect products in a world of increasing complexity?

Manual inspection can’t keep up with today’s speed and precision demands. Automated visual inspection systems, powered by AI and computer vision, are changing the game. They detect defects in real time, ensure consistency, and adapt to new patterns efficiently, against manual inspection could never deliver.

Moreover, 60% of the manufacturing businesses are currently using automated visual inspection in their quality operations. At the forefront of this transformation is Eyres.AI, helping manufacturers achieve operational excellence with advanced inspection systems.

What is an Automated Visual Inspection System?

Automated visual inspection (AVI) is the process of using cameras, sensors, and AI-powered algorithms to detect defects and verify product quality during manufacturing. Instead of relying on human inspectors, AVI captures detailed images of each product, compares them against set quality standards, and instantly flags any irregularities.

The tools that make this possible are known as automated visual inspection systems (AVIS). These systems combine hardware (such as high-resolution cameras and lasers) with software (AI and machine learning models) to ensure consistent, real-time defect detection. Unlike manual inspection, which is slow and error-prone, AVIS delivers speed, accuracy, and scalability across production lines.

In simple terms, AVI is the process, and automated visual inspection machines are the technologies that perform it, turning quality control into a reliable, data-driven function of modern manufacturing.

Importance Of Automated Visual Inspection Systems In Business Operations

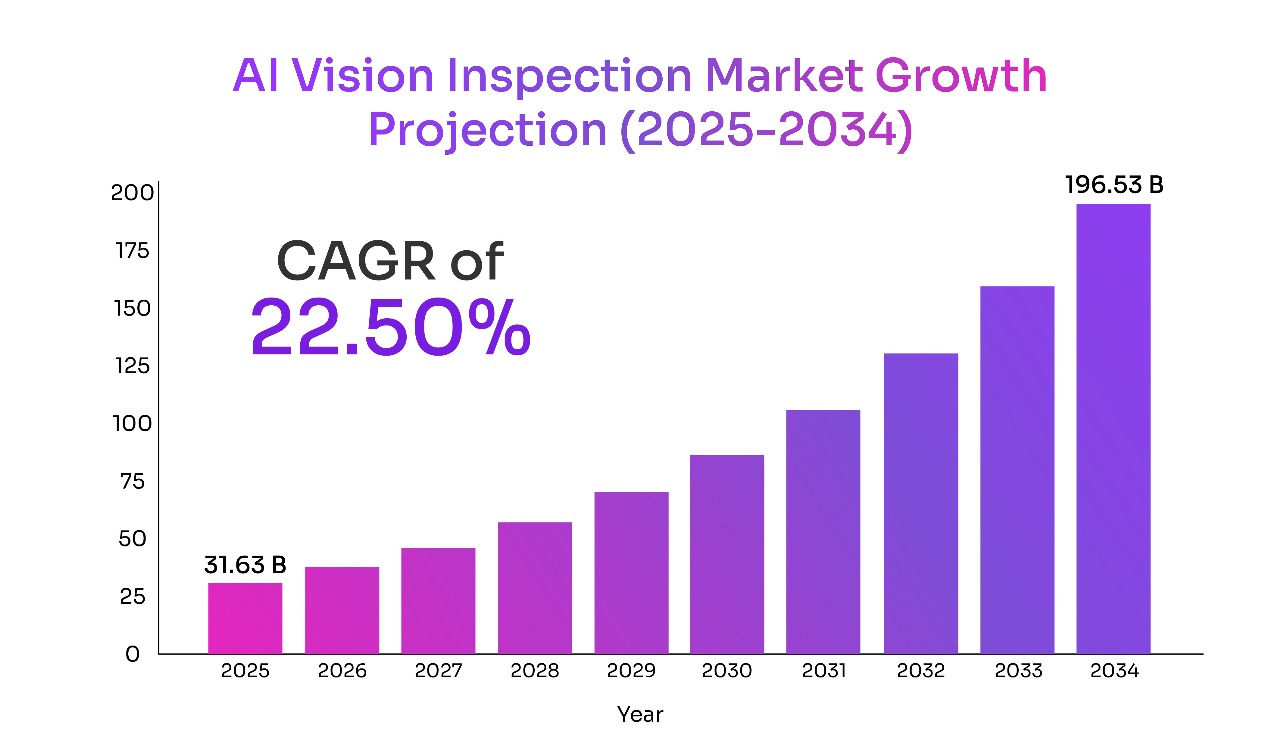

The automated visual inspection systems have already established their strong foothold in the manufacturing market. According to the reports from Market Research Future Analysis, the AI vision Inspection market is set to compound to $196.5 billion by 2034 with an impressive CAGR of 22.50%.

This growth reflects the mounting pressures manufacturers face today:

- Rising customer expectations for defect-free products.

- Stringent compliance standards across automotive, aerospace, and consumer goods.

- High costs of recalls and waste.

- Faster production cycles under Industry.

Automated visual inspection systems help manufacturers stay ahead by ensuring every product is checked, every defect is inspected, and each process is optimized. They are not just a tool for quality but a strategic asset for competitiveness.

Components Of Automated Visual Inspection Solutions

An automated visual inspection solution combines:

- Hardware –

High-resolution cameras, lasers, and sensors to capture precise images.

- Software –

AI and machine learning algorithms that analyze defects and classify anomalies.

- Machines & Systems –

Automated visual inspection machines, like conveyors or collaborative robots.

- Integration –

Direct connection with Manufacturing Execution Systems (MES) for seamless data flow and decision-making.

Together, these elements ensure that inspection isn’t an isolated activity but a core part of the production process.

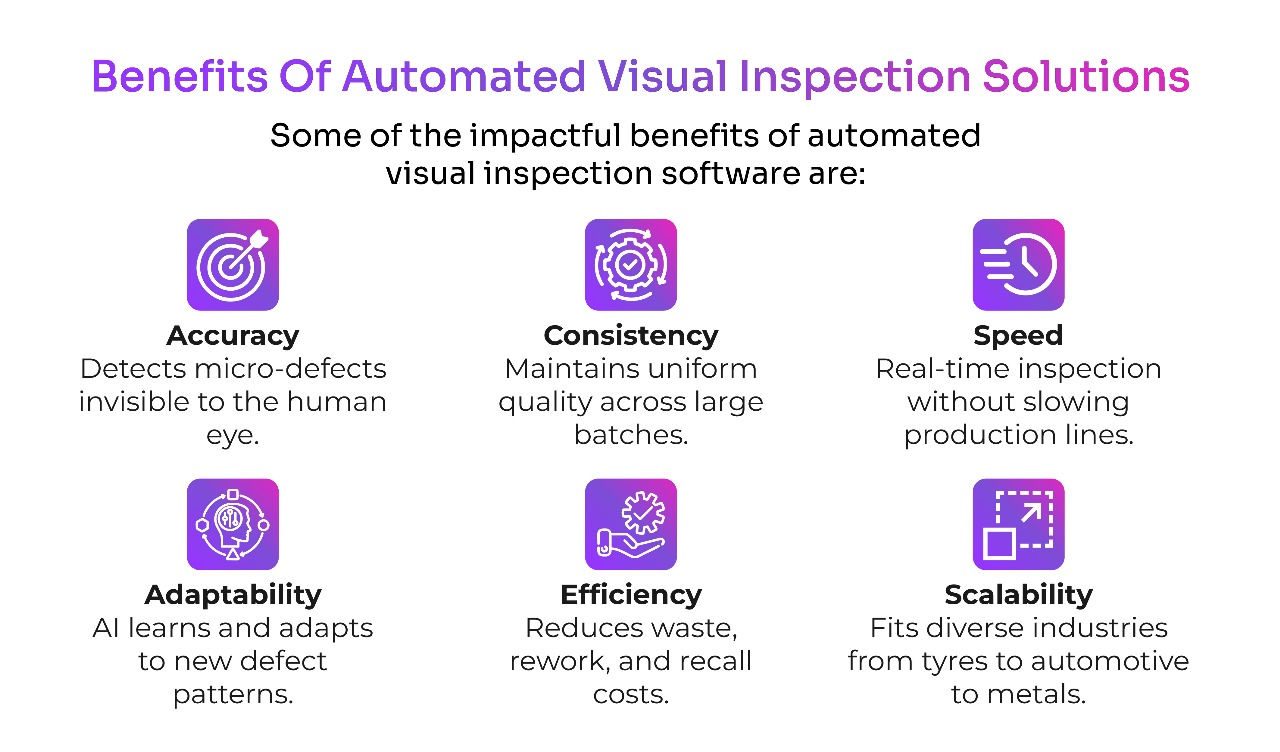

Benefits Of Automated Visual Inspection Solutions

Some of the impactful benefits of automated visual inspection software are:

- Accuracy: Detects micro-defects invisible to the human eye.

- Consistency: Maintains uniform quality across large batches.

- Speed: Real-time inspection without slowing production lines.

- Adaptability: AI learns and adapts to new defect patterns.

- Efficiency: Reduces waste, rework, and recall costs.

- Scalability: Fits diverse industries from tyres to automotive to metals.

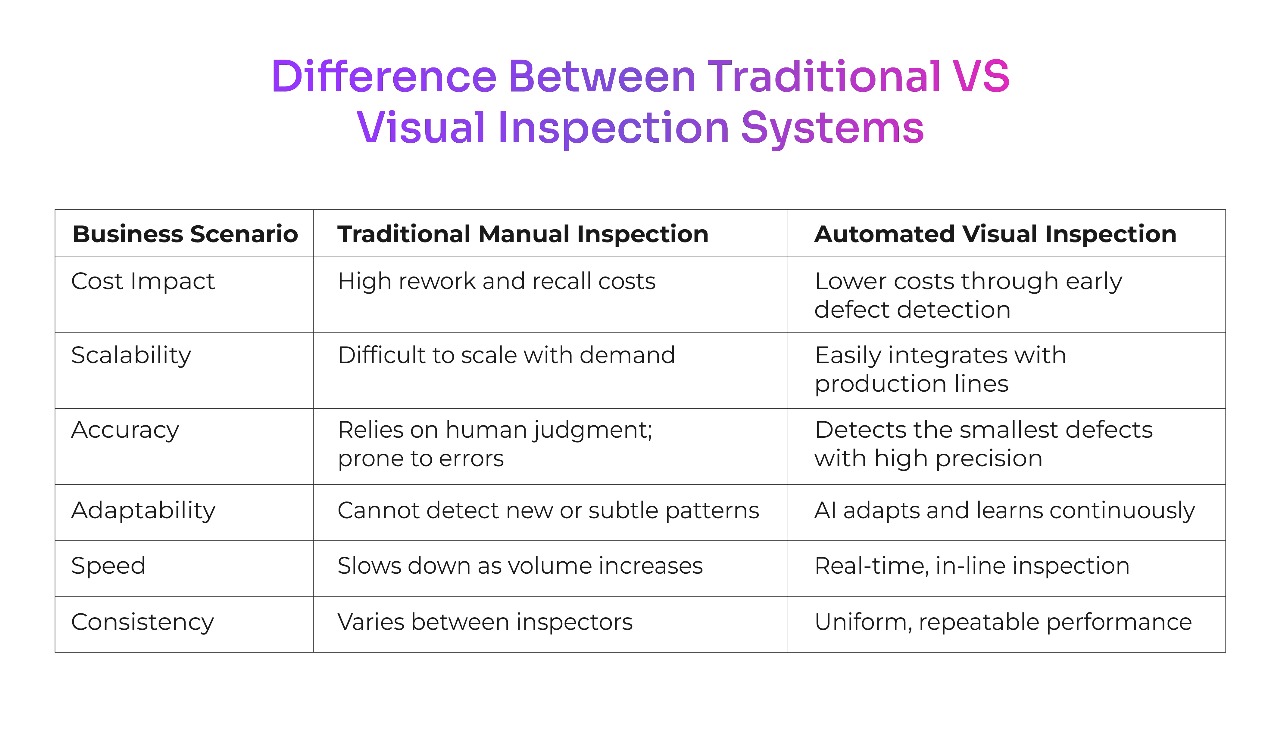

Difference Between Traditional VS Visual Inspection Systems

Check out the differences between traditional and automated visual inspection machine:

By now, the case is clear: manufacturers can no longer afford traditional inspection. The question becomes, what kind of automated visual inspection system should you choose?

Eyres.AI: Solving Real-World Inspection Challenge

Eyres.AI is heavily invested in developing AI-driven automated visual inspection systems designed to achieve zero-defect manufacturing across industries. Built on advanced computer vision and machine learning, these systems integrate seamlessly into production environments to deliver real-time, high-accuracy defect detection.

- EYRES.CUBE: Compact, semi-automatic unit with adaptive AI — ideal for low-volume, high-variability production.

- EYRES.LINEA: Fully automated in-line conveyor system with deep learning for high-speed, high-volume inspection.

- EYRES.COBOT: Collaborative robotic inspection with AI-guided precision for delicate and complex components.

In addition, Eyres.AI engineers custom-special-purpose machinery with full MES integration, enabling continuous data flow for rapid decision-making. These solutions are already addressing critical challenges in tyre inspection, metal component QC, and automotive safety systems. The outcome for manufacturers: fewer defects, reduced costs, higher efficiency, and uncompromised product reliability.

Discover how Eyres.AI can help you implement automated visual inspection systems tailored to your production needs. Book a consultation today and move closer to zero-defect manufacturing.

How to Choose the Right Automated Visual Inspection System

The right solution depends on:

- Production volume – High-speed lines benefit from in-line systems like EYRES.LINEA.

- Product variability – Low-volume or custom products work well with EYRES.CUBE.

- Component sensitivity – Precision components demand adaptive cobot systems like EYRES.COBOT.

- Integration needs – For smart factories, MES integration is essential.

By aligning system choice with production goals, manufacturers maximize ROI from automated visual inspection.

In Summary

The future of manufacturing belongs to those who embrace automated visual inspection systems. They deliver unmatched precision, consistency, and efficiency, while reducing costs and protecting brand reputation.

For manufacturers ready to step into AI-powered quality control, Eyres.AI is a trusted partner with proven solutions.

Next step: Explore how Eyres.AI can help your business achieve zero-defect manufacturing.