AI Visual Inspection Systems For Smarter & Scalable Manufacturing

Manufacturing companies today operate under increasing pressure: customer expectations for perfection, regulatory oversight tightening, and the cost of poor quality spiraling. A single defect slipping into the field can cost millions in recalls, erode brand trust, and expose the firm to legal or compliance risk.

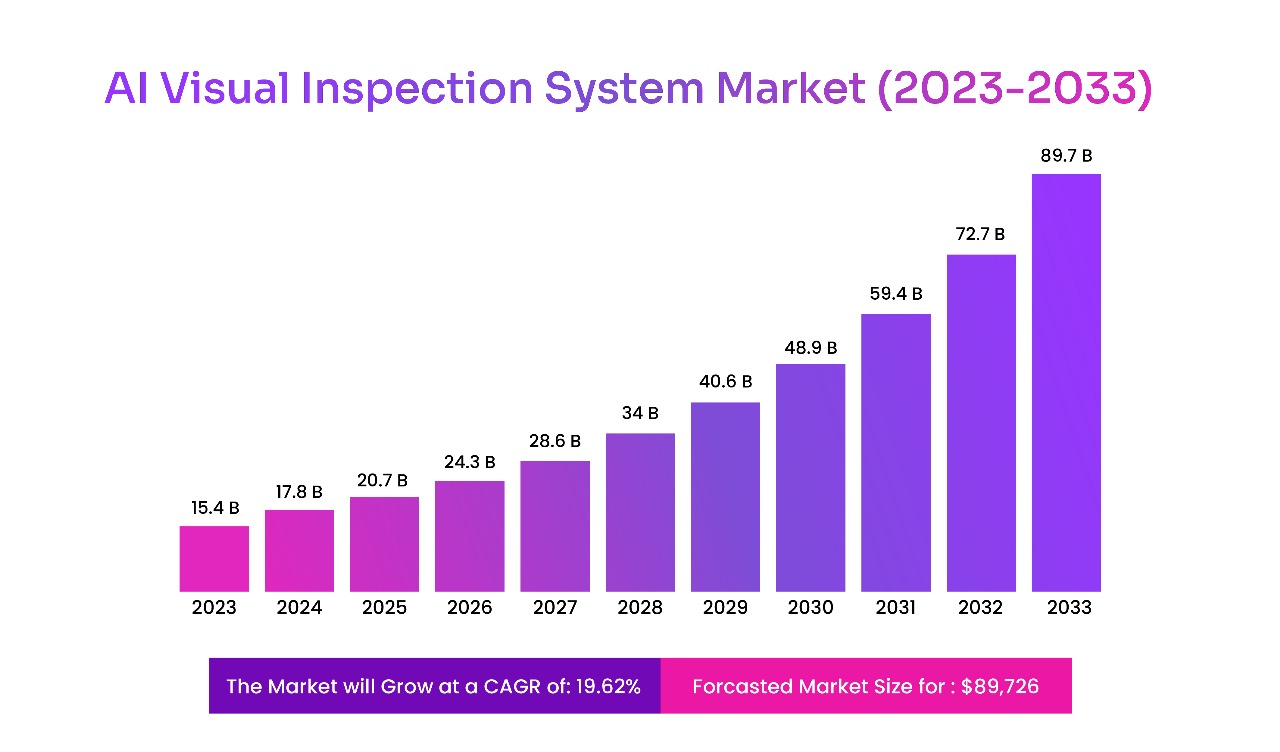

According to the report from market.us, the AI visual inspection system market was valued at about $15.4 billion in 2023 and is projected to reach nearly $89.7 billion by 2033, growing at a CAGR of 19.62%. These numbers not only show a rising demand but also the severity of the problem, prompting companies to adopt more effective inspection systems. Yet many manufacturers still rely heavily on manual or traditional machine-vision inspections, which are error-prone, slow, and inconsistent.

That’s where AI visual inspection, powered by advanced cameras, learning-capable software, and robust systems, steps in not as an optional upgrade, but as a strategic necessity. EyRes.ai specializes in delivering end-to-end AI visual inspection solutions that integrate with existing production lines to detect defects, enhance quality control, and safeguard business outcomes.

What is an AI visual inspection system?

An AI visual inspection system is an advanced quality control solution that leverages computer vision and machine learning to detect defects, inconsistencies, or deviations in products during manufacturing.

For B2B enterprises, it ensures higher accuracy, faster throughput, reduced reliance on manual inspection, and significant cost savings, ultimately strengthening compliance, product reliability, and customer trust across large-scale industrial operations.

How AI Visual Inspection Works: The Technical Backbone

An effective AI visual inspection system combines several components: high-resolution AI visual inspection cameras, lighting and imaging setups, defect detection software built on deep learning, and real-time system integration. These systems compare products/images against learned defect patterns, classify anomalies, and trigger automated alerts or reject downstream.

For example, implementing an AI-powered system lifted inspection accuracy to over 95%, significantly reducing human error and false positives. Another industry case in automotive paint-line inspection saw accuracy go from 81% to 96%, while false positives dropped 42%; the project repaid its investment in under six months.

These are not outliers. Across sectors, companies are recording 50% reductions in component defect rates, 35% increases in production efficiency, and 25% reductions in inspection cost with video analytics and AI inspection systems.

Benefits Of AI Visual Inspection Systems In Business Production

AI visual inspection software offers advantages that extend far beyond defect spotting:

- Higher Output → up to 40% reduction in downtime with automated defect detection.

- Process Optimization → insights into recurring issues help improve production efficiency.

- Predictive Quality Control → AI visual inspection solutions shift from reactive to preventive assurance.

- Safety Enhancement → reduced manual handling lowers workplace accidents.

- Regulatory Compliance → consistent, auditable quality checks ensure adherence to global standards.

- Scalability → AI visual inspection cameras can handle high-speed and high-volume production seamlessly.

By combining speed, accuracy, and predictive intelligence, manufacturers can strengthen resilience and improve competitiveness in a zero-defect economy.

Why AI Visual Inspection Matters Now

Manual inspection is slow, error-prone, and costly. Research shows AI-driven systems can reduce defects by up to 50% and accelerate inspection cycles by 30–50%, leading to 25% higher throughput.

For B2B manufacturers, this isn’t just about saving costs. It is about scaling quality, avoiding recalls, and safeguarding brand credibility in a zero-defect economy. Companies like Ford and Samsung are already leveraging AI-powered inspection to slash recalls and boost yields.

With EyRes.AI, manufacturers can move beyond detection into predictive quality control, identifying risks before they manifest. This transition from reactive checks to proactive assurance creates resilience, reduces waste, and ensures every product that ships strengthens customer trust.

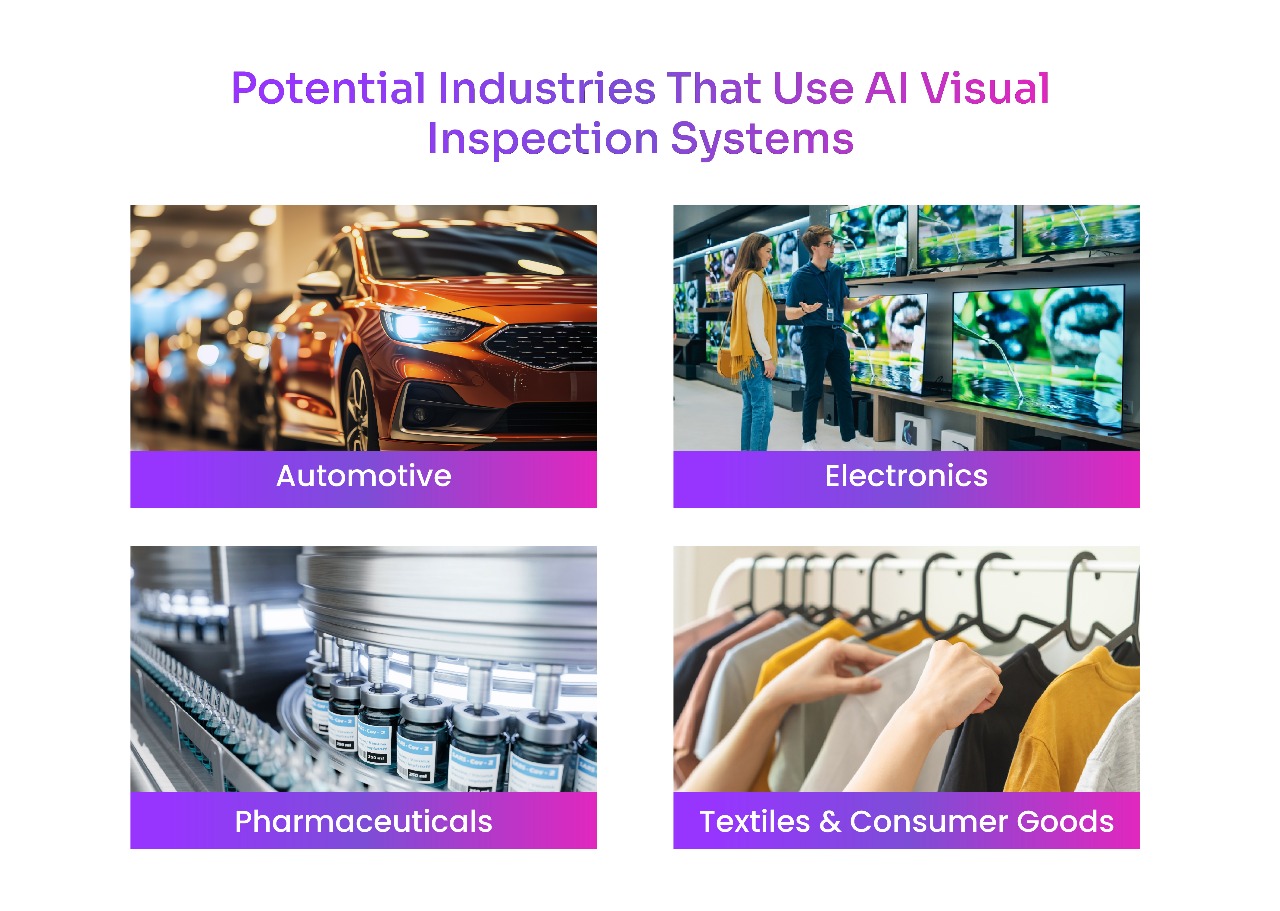

How Industries Leverage AI Visual Inspection Systems

AI visual inspection systems are transforming quality control across industries:

- Automotive: Detecting paint flaws, assembly gaps, and welding defects with precision.

- Electronics: Inspecting microchips, solder joints, and circuit boards where even a minor error can trigger large-scale failures.

- Pharmaceuticals: Ensuring packaging integrity, correct labeling, and contamination-free production for regulatory compliance.

- Textiles & Consumer Goods: Identifying fabric inconsistencies or cosmetic defects at scale.

In each case, AI visual inspection software integrates seamlessly with existing production lines, using high-resolution cameras and deep learning models to deliver unmatched speed and accuracy.

By reducing human dependency, these systems drive consistency across global operations. Forward-looking manufacturers leverage AI visual inspection solutions not just for quality control, but also as a strategic differentiator in competitive markets.

Critical Challenges Involved with Manual Inspection

- Human error & fatigue → Inspectors can miss up to 20–30% of defects under pressure.

- Inconsistency → different inspectors may classify the same defect differently.

- Scalability issues → not feasible for high-volume or high-speed production lines.

- High operational costs → large workforce required for round-the-clock inspection.

- Compliance risk → missed defects can lead to recalls, fines, or reputational damage.

AI visual inspection systems address these bottlenecks by ensuring real-time, consistent, and scalable defect detection.

How EyRes.AI Transforms Quality Control

EyRes.AI delivers an end-to-end AI visual inspection platform designed for enterprise scalability, moving manufacturers from reactive defect detection to predictive quality assurance. Its flagship system, Eyres.LINEA, combines high-resolution AI visual inspection cameras with deep learning algorithms to detect surface anomalies and dimensional deviations in real time.

Hence, making it ideal for high-speed production lines across industries. Specialized solutions such as Rubber and Plastic Inspection ensure polymer components are free from surface imperfections and material inconsistencies, while Tapered Roller Bearings (TRB) Inspection provides micron-level precision for critical automotive and industrial components.

Metals and Diecasting Inspection identifies cracks, dents, and deviations to maintain structural integrity, and Tyre Defect Detection & Tyre OCR automate the inspection of tyres and verify markings for safety and compliance. With modular architecture, continuous learning models, and seamless integration with existing workflows, Eyres.AI empowers manufacturers to achieve consistent quality, reduce recalls, and future-proof operations in a competitive, zero-defect economy.

Book a free consultation with Eyres AI experts and explore how our solutions can elevate your quality control processes.

In Summary

AI-powered visual inspection is reshaping manufacturing by making quality control faster, smarter, and more reliable. With Eyres AI’s advanced systems, businesses can reduce errors, cut costs, and boost operational efficiency while ensuring uncompromised product quality. By combining automation with intelligence, Eyres AI positions enterprises to stay competitive in today’s demanding markets.